Machining

The machining process is performed according to the own documentation (developed in the department of construction and technology) or entrusted by the client.

Scope of work:

- production of threaded connections of various types, including the API standard

- machining of large-size details

- production of spare parts according to own or entrusted documentation

- turning and threading of long shafts and pipes up to 300 mm in diameter

- regeneration and execution of parts of heavy industry devices (including drilling equipment)

Current technological possibilities:

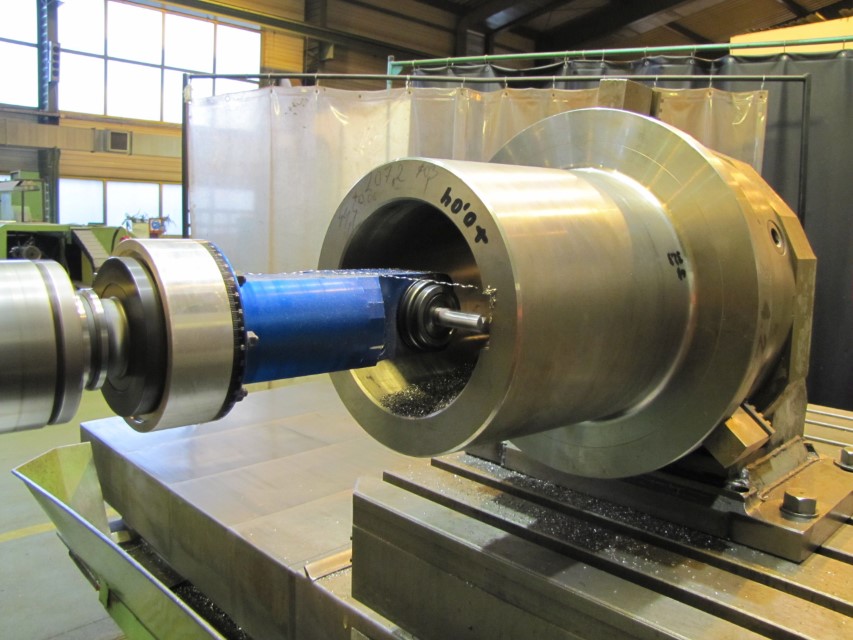

TURNING

- on a numerically controlled lathe with spindle passage 320 mm and lifting capacity in centers 6000 kg lifting capacity in centers 6000 kg,

- on "tubular" lathes with a lifting capacity of 6000 kg and a bed of 3000 mm long,

- on conventional lathes up to ø930 length 3000 and weight 4000 kg,

- on automatic lathes up to ø290 and length 1000 mm.

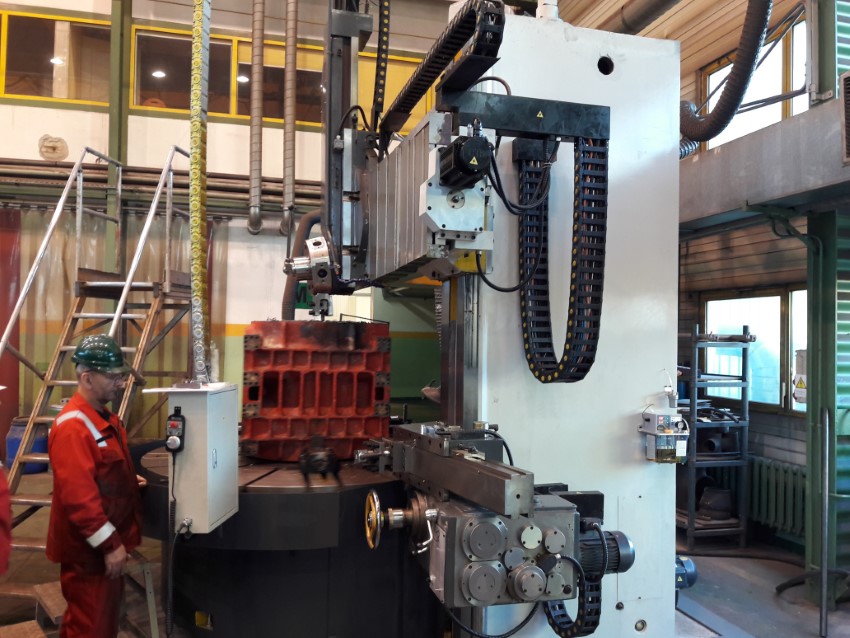

MILLING

- on a numerical drilling and milling machine with a table capacity of 4000 kg and a working space of 1400 mm x 1000 mm and a height of 1200 mm, conventional

GRINDING

- planes with dimensions of 600 × 200

- shafts to dim. ø500 × 1470 and weight 400 kg

DRILLING

- holes on the coordinate drilling machine

- holes on a radial drilling machine

DIFFERENT

- Slotting slotting - 350 mm pitch

- Cutting with a band saw to a diameter of 350 mm

- Numerical cutting with a band saw with a feeder up to 250 mm in diameter