Welding works

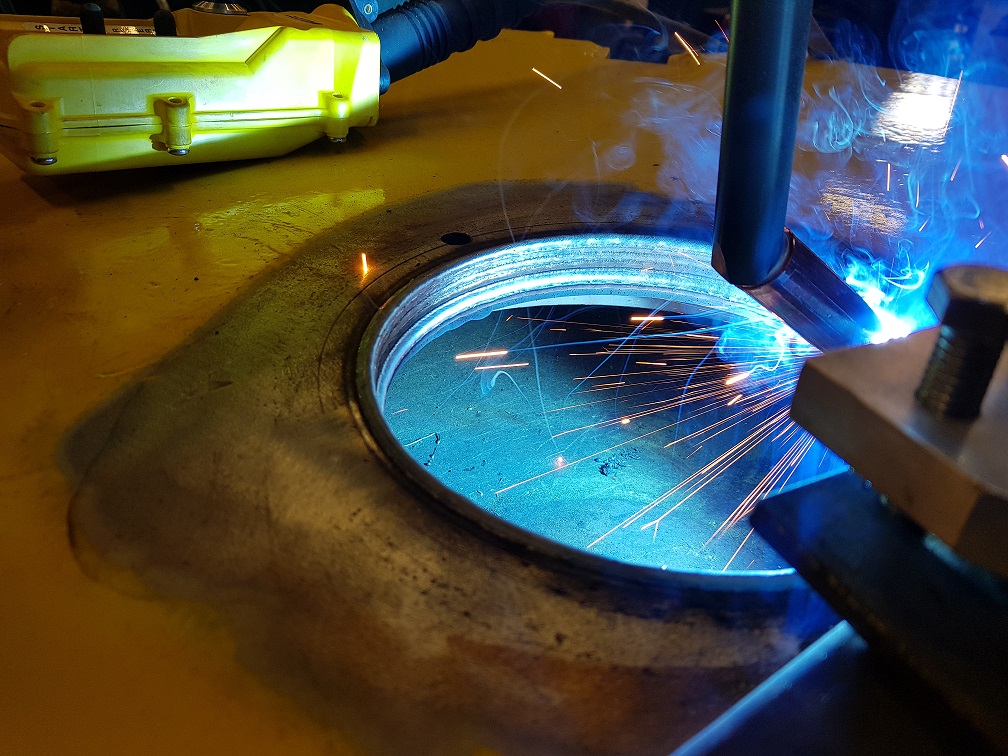

Workshop performs welding work based on qualified welding technologies (WPQR - Welding Procedure Qualification Record). The basic welding processes are:

- semi-automatic welding in active gas shielding (MAG)

- welding with coated electrodes (MMA)

- inert gas welding (TIG) and gas welding

Welding with hard-wearing materials and hard soldering are also performed. Welders have Qualification Certificates and the supervision over the quality of conducted works is carried out by the Technologist and Engineer Welding. Welding machines with a capacity of 32 tons allow for the production of large-size elements.

The qualifications of welders allow welding of black, stainless steel and aluminum.

BASIC WELDING ACTIVITY:

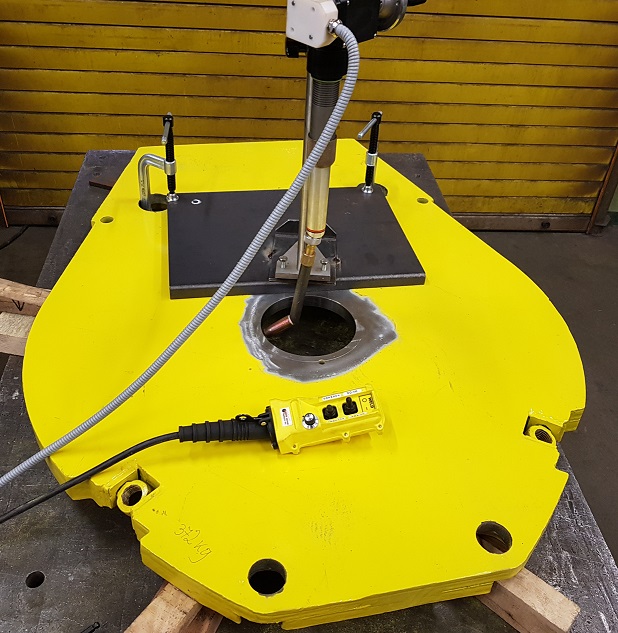

- repair and production of steel tanks

- repair and manufacture of high pressure fittings (350 and 500 bar) and diameters 2 ", 3", 4 ", 5"

- repair and regeneration of special tools and components of construction machines by hard surfacing, soldering and application of hard sinters with Baildonit and Castolin materials

- regeneration of piston and vortex pump bodies, spare parts, subassemblies

- repair and production of steel structures made of low-carbon steels (S235JR, S355J2)

- repair and production of heavy containers

- repair and production of stainless steel and aluminum construction elements

We provide welding services in our workshop as well as in the place indicated by the customer.