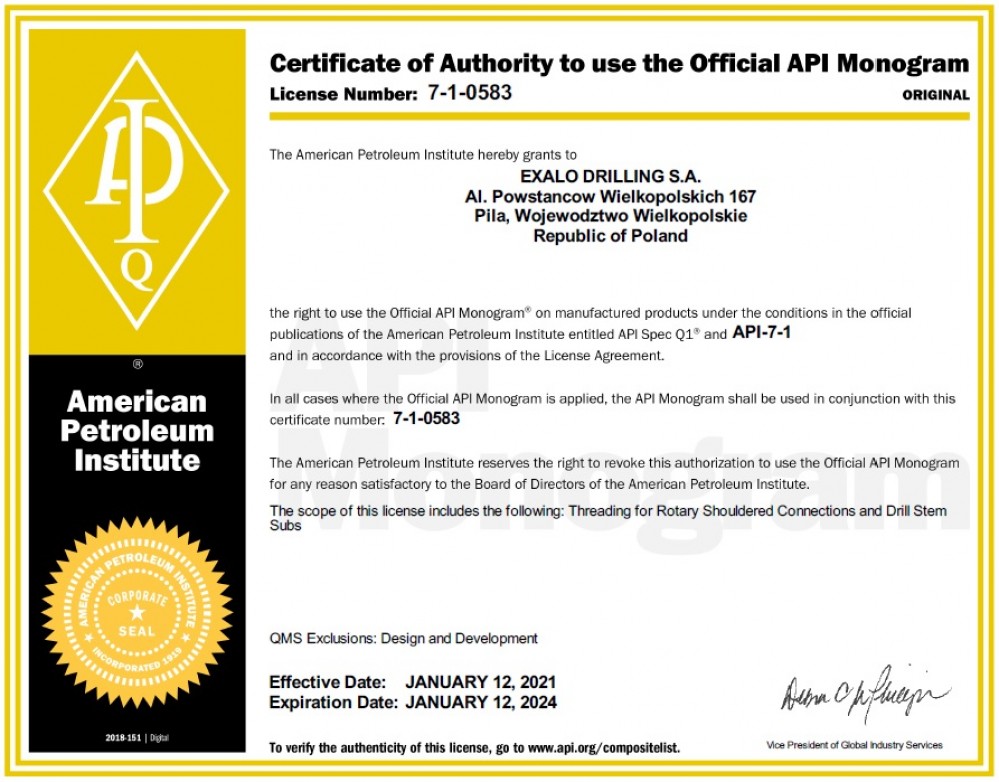

Exalo Mechanical Workshops in Pila producing and regenerating A, B and C type drill stem subs and D type manipulating subs, in accordance with API-7-1 / ISO 10424-1. We make new and regenerate NC, REG, FH threaded tool connections, in accordance with API-7-2 / ISO 10424-2, and the connection of casing and service pipes according to customer requirements. We mark our products with the API monogram for both sub and thread connections.

Exalo Mechanical Workshops in Piła have the API 6A monogram that allows the production of certified flanges and adapters spools as well as test and blind flanges at the PSL 3 level up to a maximum pressure of 15,000 PSI.

The Exalo Mechanical Workshop in Piła is the only plant in Poland to have a license to manufacture Grant Prideco premium threads for Grand Prideco EIS and Express (VX) types.

We are experienced in production of:

- Grant Prideco Express™ (VX™) – 4”

- Grant Prideco EIS™ - 5 ½”

Grant Prideco Double Shoulder Joints and EIS are high quality joints for drill pipes in sizes 2 3/8 ”to 6 5/8”.

Both connections offer a versatile alternative to standard API connection designs when higher operational torque and tool joint wear allowance are desired, and they are fully interchangeable with corresponding API NC or FH counterparts. GPDS and EIS are proven connections that provide increased torsional capacity, promote more streamlined configurations, and tolerate more tool joint wear than standard API rotary-shouldered connections.

Advantages of Grant Prideco connections:

a. Improved Torque Transfer Capability:

Streamlined GPDS and EIS connections provide 20 to 50% more torque than API rotary-shouldered connections of the same dimensions. This additional strength provides the required torque for drilling to extended depths or in more demanding environments.

b. Extended wear allowence:

GPDS and EIS connections significantly extend the life of the connection, tolerating greater internal wear due to its increased torsional capacity.

c. Interchangeability:

Although similar to other API connections, these connections incorporate an internal secondary torque shoulder. Both use the same thread form and are interchangeable with their API counterpart connection. The double shouldered pin secondary torque shoulder runs out without shouldering in the back of the API box connection. Similarly, the API pin will make up to the double shouldered box. “Interchangeability” means that the connections will mate together, make up, and function; however, the performance properties will be limited to those of an API connection. GPDS and EIS are not interchangeable with each other.

d. Slim profile and increased hydraulics.

The GPDS and EIS connection’s increased torsional strength enables tool joint dimensional optimization more suitable for the pipe body torsional strength. Both connections can be configured with a smaller OD and larger ID compared to standard API connections, contributing to improved hydraulic performance. The GPDS and EIS design also provides a true flush ID through the mated tool joint assembly. There is no gap or change in the ID from the box to the pin, creating a smoother fluid flow with less turbulence and eliminating the opportunity for trapped cement and cuttings.